Hot-dip galvanized and painted precision tubes resist corrosion even in extreme environments

One of the most severe corrosion test that is conducted in SSAB’s R&D laboratory in Hämeenlinna is cyclic salt spray exposure. It is performed accelerated manner in unique corrosion chamber that sprays neutral saline solution on the test specimens aiming to speed up the formation of different corrosion products. Salt spray period is followed by warm air drying period. This wet-dry cycle typically lasts for 24 hours, and it is repeated multiple times, often at least 1000 hours (6 weeks).

This typically 1000 hours lasting test time is called Accelerated Corrosion Test (ACT), which is defined by several test standards, for example EN ISO 9227 or EN 13523-8, which are applicable in SSAB.

Cyclic salt spray test imitates extremely saline atmosphere which is not typical for many natural environment on Earth. Perhaps some marine locations fulfils the same climate conditions to salt spray chamber in laboratory. Therefore the main purpose in accelerated corrosion testing is to cause rapid electro chemical rusting phenomena and to compare the performance of the simultaneous samples to each other.

Picture 1. Erichssen Q-FOQ salt spray chamber is used in corrosion resistance studies at SSAB.

Tubular products may end up to extreme environments

Typical application for precision tubes is a body of a furniture, such as a chair, or outdoor ladders for buildings. These products may be used for indoor, outdoor or for more special environment. Depending on the conditions of the usage and/or the desired visual appearance, precision tubes may be coated. Coating is typically colored organic paint film or chromium as plating. In any harsh applications, painted steel tube can be also hot-dip galvanized in prior to painting to increase corrosion protection in case of water penetration thru film via damages of paint surface. “It is essential to understand the end use of the product, meaning what kind of environment they will end up and what is the expectation of the life time for the product.”, says Antti Markkula, Head of Technical Development, Tubular Products.

In special locations, such as marine areas, sanitary facilities or any other spaces of high relative humidity, the product can be affected by extreme corrosion attack. Corrosion phenomena may further speed up by liquids including salts, ammonia, sulphates or any other corrosion driven substances. In these circumstances, the products, such as chairs or ladders, are prone to rust and lose their appearance faster than their expected life time. Therefore SSAB has plenty of test protocols to evaluate precision tubes’ durability in extreme conditions. “We have several decades of experience in testing and evaluation for all kinds of precision tubes; cold-rolled and several ways of metal coated tubes and also their powder painted versions. Long experience provides us good tools to estimate the durability of our products in various customer applications”, Antti sums up.

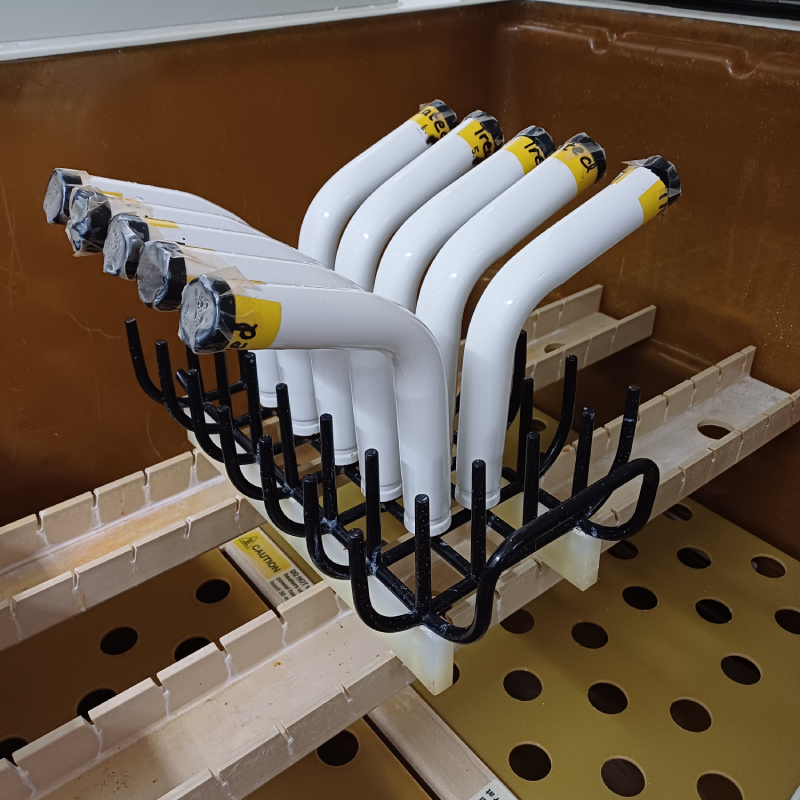

Picture 2. Orientation of test tubes simulates their natural position where no liquid is allowed inside the tube and the corrosion phenomena are evaluated on the outer surface of the tube body.

Coated precision tubes provide good durability against corrosion

Recently, SSAB conducted a special evaluation for one customer case. The tubes that were traditionally used in this application were stainless, because the use application included repeating conditions of high humidity, water showering and potentially corrosion boosting substances diluted in water. The aim of the study was to evaluate the performance of SSAB hot-dip galvanized precision tubes in comparison to cold-rolled tubes with no galvanization and to reference tubes made from stainless steel. Test specimens were prepared similarly to minimize variables in tube manufacturing, component engineering, chemical pre-treatment, powder coating and assembly. Cyclic salt spray test was conducted for several replicates to enable better averages and test time was super long, up to 2000 hours (12 weeks).

First some microscopical cross-cut imaging was taken from different areas of the specimen to identify the variation of paint film thickness which can affect the corrosion speed. The thinner is the film, the faster it typically allows salty water to penetrate down to the surface of metal.

Results were pretty convincing. Antti concludes that “Cold rolled specimens started to generate red-rust everywhere relatively fast and approximately after some 150 hours, whereas galvanized variant only created some whitish zinc hydroxide around the artificial scratch where the metallic zinc dilutes to water forming so called white-rust. This reaction is typical and expected for zinc which principal purpose is to sacrify and protect steel core from red-rust.”

Results show the clear difference in performance of the precision tubes. Without galvanization, the cold-rolled tubes start to rust fast and aesthetically product does not look good. In case on galvanized tubes, the performance reach really good level. “I admit that in the longest-run the stainless steel grades likely perform the best, but SSAB’s hot-dip galvanization improves the durability of carbon steel grades significantly. After this extreme testing, it is aesthetically similar to painted tube made from stainless steel grades, and most likely exceed the expectation for durability in this end use application. The most valuable result was to realize that adequate performance can be reached with significantly lower cost of used raw material. We can imagine the cost difference between stainless steel and metal coated carbon steel alternatives. I think there is quite nice opportunity to customer to optimize cost/quality ratio in collaboration with SSAB”, Antti convinces.

Picture 3. Cold-rolled steel (1.2), galvanized steel (3.2) and stainless steel (5.2) tubes in comparison after 11 weeks (1850 hours) in cyclic salt spray test. The weakest performing areas of specimens are around the artificial scratch down to metal surface and the embossed circle on lower part of the tube where the paint film is thinnest.

SSAB conducts customer and application specific evaluations and testing in R&D laboratory of Hämeenlinna Works. “We challenge all the designers who are working with precision tubes to find more optimal and cost-efficient solutions for your purposes”, encourages Antti Markkula, Head of Technical Development, Tubular Products.

More information on SSAB Tubular products and precision tube alternatives can be found from www.ssab.com/tubular

Attachments

Category and tags