General Product Description

Strenx® P700 is a pressure vessel steel with minimum yield strength of 670 - 700 MPa depending on thickness.

Strenx® P700 is available in four grades, which meets or exceed the requirements of P690Q, P690QH, P690QL1 and P690QL2 in EN 10028-6.

Typical applications are demanding loadbearing structures exposed for pressure and elevated temperatures.

Mechanical Properties

Mechanical properties in room temperature (20°C)

(mmin)

(mmin)

(min MPaksi)

(MPaksi)

(min %)

(mmin)

(mmin)

(min MPaksi)

(MPaksi)

(min %)

For transverse test pieces.

Yield strength

Guaranteed minimum yield strength Rp02, in MPa, at elevated temperature only for grade P690QH.

(mmin)

(mmin)

(mmin)

(mmin)

For transverse test pieces according to EN 10028.

If agreed at the time of inquiry and order, these values also apply to the P690QL grades with specified low temperature properties.

Impact Properties

Charpy V 10x10 mm test specimen 1)

Charpy V 10x10 mm test specimen 1)

Charpy V 10x10 mm test specimen 1)

Charpy V 10x10 mm test specimen 1)

Charpy V 10x10 mm test specimen 1)

Charpy V 10x10 mm test specimen 1)

1) Unless otherwise agreed, transverse impact testing according to 10028. For thicknesses between 6.0 - 11.9 mm, sub size Charpy V-specimens are used. The specified minimum value is then proportional to the cross-sectional area of the specimen compared to a full-size specimen (10 x 10 mm).

Chemical Composition (ladle analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

The steel is grain refined. *) Intentional alloying elements.

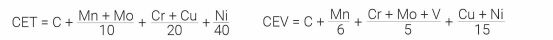

Carbon Equivalent CET(CEV)

Thickness

Tolerances according to EN 10029 Class B. More narrow tolerances are available on request.

Length and Width

Tolerances conform to EN 10029 or to SSAB’s standard after agreement.

Shape

Tolerances according to EN 10029.

Flatness

Tolerances according to Strenx® Flatness Guarantee Class C, which are more narrow than EN 10029 Class N.

Surface Properties

According to EN 10163-2 Class A, Subclass 3.

Delivery Conditions

The delivery condition is Quenched and Tempered. The plates are delivered with sheared or thermally cut edges. Untrimmed edges after agreement.

Delivery requirements can be found in SSAB’s brochure Strenx® Guarantees or on www.ssab.com.

Fabrication and Other Recommendations

Welding, bending and machining

Recommendations are found in SSAB’s brochures at www.ssab.com or consult Tech Support.

Strenx® P700 has bending guarantees according to Strenx® Bending Guarantees Class A. Workshop guidelines for Strenx® P700 refer to the same recommendations as for Strenx® 700 E. Strenx® P700 has obtained its mechanical properties by quenching and subsequent tempering. The properties of the delivery condition cannot be retained after exposure to temperatures in excess of 580°C.

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on this product. Grinding, especially of primer coated plates, may produce dust with a high particle concentration.

Show specs in: