General Product Description

Duroxite® 500 is an iron-based steel alloy overlay deposited on a mild steel backing plate. It is designed for a good combination of sliding wear and high impact applications for both dry and wet (slurry) abrasive environments. It works well at ambient or elevated temperatures up to 1100 °F (600 °C). The product is available in single and double layers.

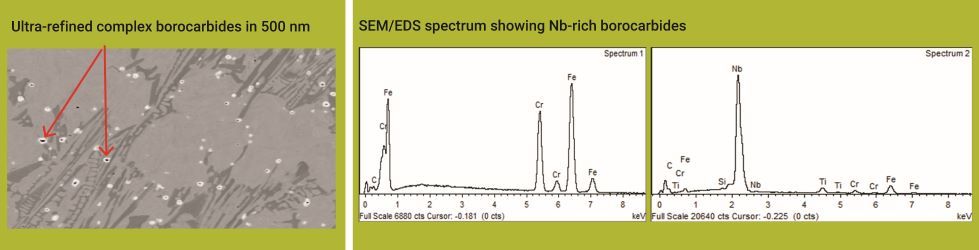

Duroxite® 500 consists of specially formulated abrasive materials employing a uniform glass-forming melt chemistry that allows high undercooling to be achieved. The overlay contains a unique high volume of ultra-fine chromium-niobium-rich complex borocarbide phase with a grain size refined down to 500 nm. The borocarbides are completely wetted in a ductile matrix preventing premature pull-out delamination, crack nucleation and bridging. This results in a product with significantly improved service life that maintains high toughness in sliding wear and high impact applications. Duroxite® 500 has a better combination of impact and wear resistance than those of traditional chromium carbide overlay.

Key Benefits

- Duroxite® 500 is mainly designed to withstand the applications involving abrasion wear and high impact.

- Duroxite® 500 overlay contains ultra-fine complex borocarbides which is 200 times finer comparing with primary carbides in traditional chromium carbide overlay (Duroxite® 100).

- The wear resistance of Duroxite® 500 is very similar to that of Duroxite® 100 with the weight loss in ASTM G65-procedure A, 0.18g maximum. Duroxite® 500 also maintains a consistent wear resistance from surface down to 75% of the overlay.

- The impact resistance of Duroxite® 500 is six times better than that of Duroxite® 100 in the lab test.

- Has uniform through-thickness hardness of 67 to 70 HRC for single and multiple-layer overlay. Maintains a high hardness of approximately 60 HRC after exposure to high temperatures up to 1100 °F (600 °C).

Typical Applications

Duroxite® 500 is suitable for use in the mining, power generation, cement, oil sand, steel production, waste handling, and pulp and paper industries. Some specific applications include:

Mining

Cement

Oil sands

Dredging

Power

Agriculture

For more information on applications see the Duroxite® Product brochure.

Standard Dimensions

Other plate sizes and custom thicknesses can be produced upon request.

Standard plate sizes

Other plate sizes and custom thicknesses can be produced upon request.

Mechanical Properties

1) Surface hardness is measured on machined flat surface just below overlay surface.

2) ASTM G65 - Procedure A weight loss, is a standard test measuring sliding abrasion resistance using a dry sand/rubber wheel apparatus. ASTM G65-Procedure A is the most severe test method.

3) ASTM G65 - Procedure A weight loss, wear test is conducted at 75% depth of the overlay materials to ensure consistently good wear resistance from the top surface through to the depth of 75% of the overlay.

Microstructure

Duroxite® 500 overlay contains an ultra-fine complex borocarbide phase down to approximately 500 nm in a ductile matrix. The typical volume fraction of borocarbides is maintained between 60 to 70% to form a uniform hard matrix. The SEM (Scanning Electron Microscopy) / EDS (Energy Dispersive Spectrometry) analysis of the Duroxite® 500 overlay confirms that the refined borocarbides are niobium-rich borocarbides, and chromium-rich borocarbides dispersed in an iron-based matrix. The ultra-fine borocarbides are approximately 200 times finer than the traditional chromium carbides.

Thickness

Tolerances according to Duroxite® Thickness Guarantee.

Duroxite® overall and overlay thickness tolerances can be guaranteed within ±10% of specified thickness.

Flatness

Plate flatness tolerance can be guaranteed as shown below over 1.5 m (5’) plate length for plate dimensions less than or equal to 1.5 m (5’) x 3.0 m (10’).

For custom sizes, please consult your local sales representative or Hardox Wearparts center for flatness guarantees.

Delivery Conditions

Duroxite® 500 is supplied in an as-welded condition.

Fabrication and Other Recommendations

Welding, cutting, forming and machining

Recommendations can be found in the Duroxite® Product brochure, or consult your local technical support representative.

Bendability for Duroxite® overlay plate are according to Duroxite® Bending Guarantees.

Safety precautions

When welding or cutting Duroxite® products, gases and harmful fumes are produced that are chemically complex and difficult to classify. The major toxic component in the fumes is hexavalent chromium. The proper exhaust ventilation equipment and fume-extraction torches are recommended, as well as suitable protective clothing and respiratory protection for operators.