General Product Description

Duroxite® 200 Pipe is manufactured by depositing specially formulated abrasive materials on a mild steel base using a traditional arc welding process. The overlay material is composed of primary chromium-rich carbides and refined multiple-alloy complex carbides dispersed evenly in a ductile eutectic austenite matrix. The hardfacing overlay pipe is designed with extreme wear resistance for working in a severe sliding wear environment. Duroxite® 200 Pipe is available with single or double overlay passes. Schedule 40 and Schedule 80 steel pipe as well as tubing can be used as base pipes to make Duroxite® 200 Pipe. Duroxite® 200 Pipe can be fabricated as square-to-round transitions, elbows, T or Y-shaped, or as long sweeps.

Key Benefits

- Same wear resistance guaranteed from surface down to 75% of the overlay

- Optimal carbide composition to provide good combination of wear resistance and homogenous bonding

- Longer service life and better wear resistance compared to traditional chromium carbide hardfacing pipe

Typical Applications

Duroxite® 200 Pipe is widely used in the mining, cement, oil sands, dredging, recycling and steel production industries. Some specific applications include:

Mining

Cement

Dredging

Steel

For more information on applications see the Duroxite® Product brochure.

Standard Dimensions

200 - 600 mm

600 - 900 mm

0.9 - 3.0 m

1.8 - 3.0 m

- Lengths cut or fabricated as needed

- Stainless steel and other pipe grades available

- Custom diameters, lengths and gauge sizes are available upon request.

- Diameters larger than 0.9 m can be fabricated from formed Duroxite® 200 plate.

Mechanical Properties

1) Surface hardness is measured on machined flat surface just below overlay surface.

2) ASTM G65 - Procedure A weight loss, is a standard test measuring sliding abrasion resistance using a dry sand/rubber wheel apparatus. ASTM G65-Procedure A is the most severe test method.

3) ASTM G65 - Procedure A weight loss, wear test is conducted at 75% depth of the overlay materials to ensure consistently good wear resistance from the top surface through to the depth of 75% of the overlay.

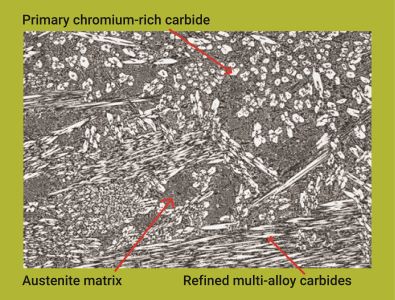

Microstructure

The microstructure of Duroxite® 200 pipes contains primary chromium-rich carbides and refined multiple-alloy complex carbides with a typical hardness of 2500 to 3000 HK*) dispersed evenly in a ductile eutectic austenite matrix. The typical volume fraction of primary chromium-rich carbides is maintained between 30 to 40% with 7 to 10% of multi-alloy complex carbides.

*) HK is the Knoop microhardness used primarily for very brittle materials.

Fabrication and Other Recommendations

Welding, cutting, forming and machining

Workshop recommendations can be found in the Duroxite® overlay brochure or you can consult your local technical support representative for more information.

Safety precautions

When welding or cutting Duroxite® products, gases and harmful fumes are produced that are chemically complex and difficult to classify. The major toxic component in the fumes is hexavalent chromium. The proper exhaust ventilation equipment and fume-extraction torches are recommended, as well as suitable protective clothing and respiratory protection for operators.