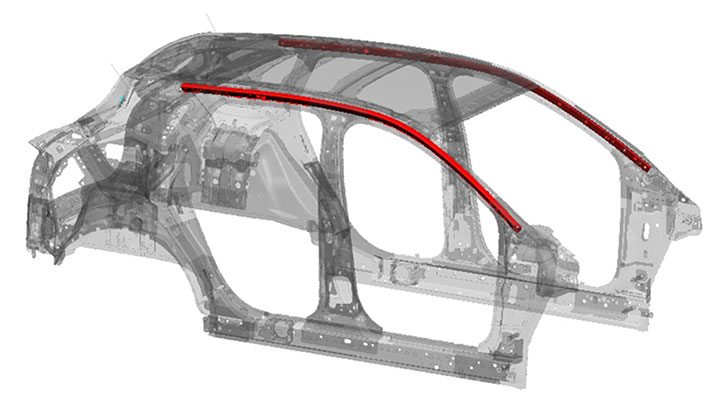

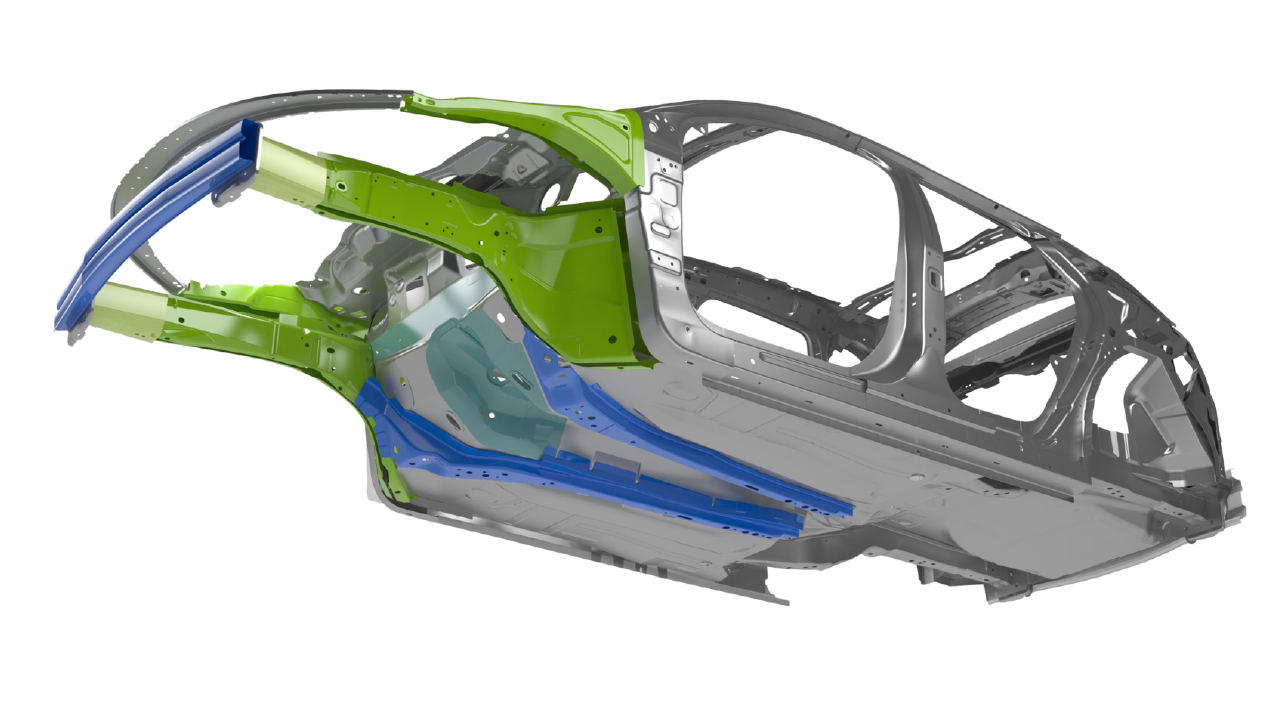

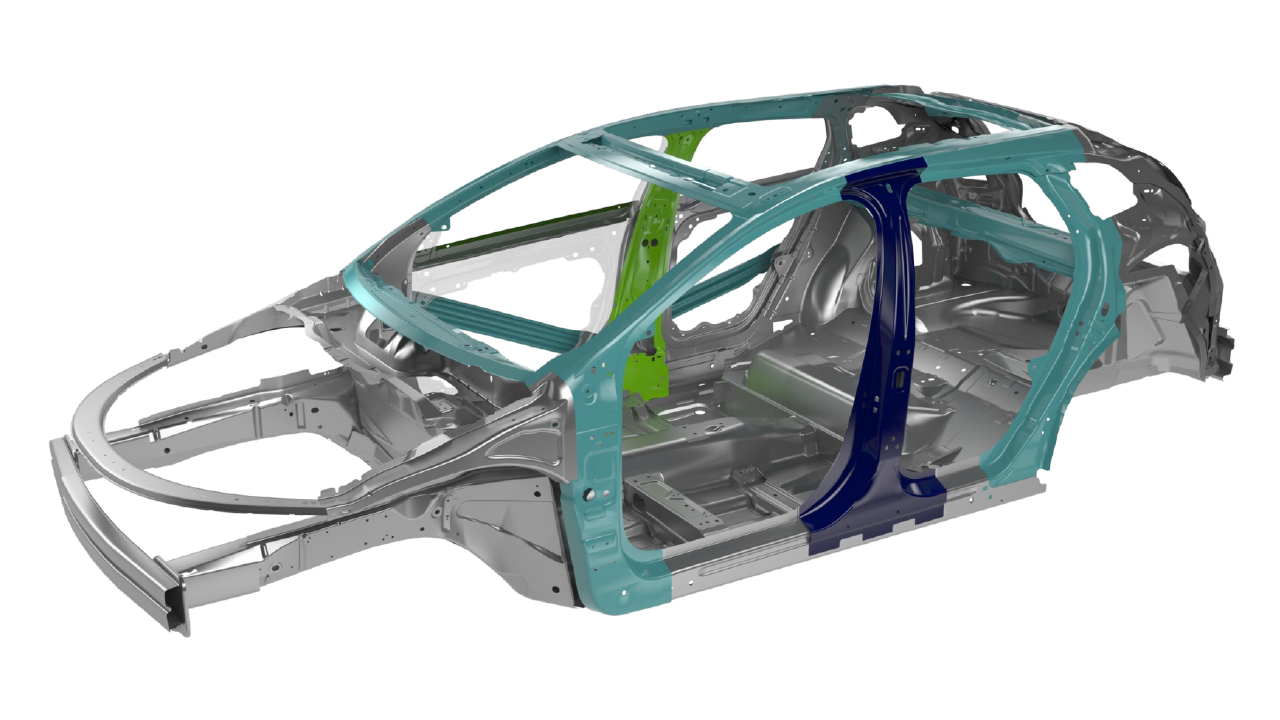

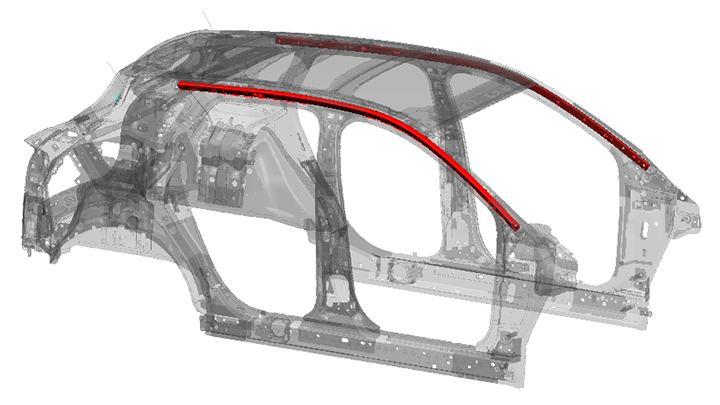

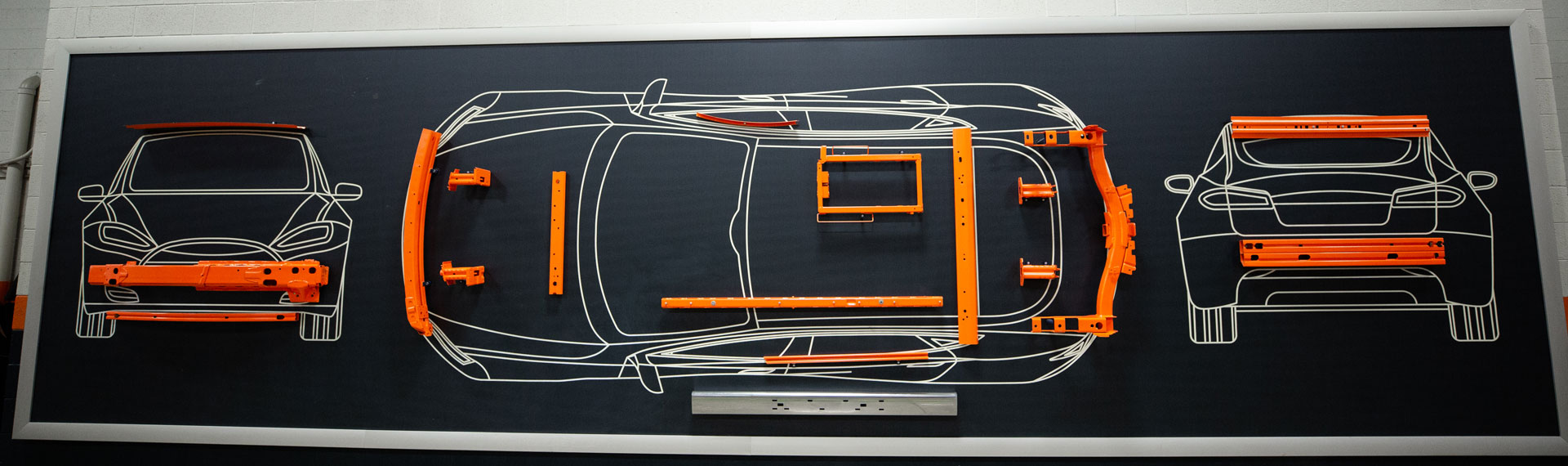

Structural automotive body components in AHSS steel

Structural automotive body components — also known as “body-in-white” components — continue to benefit from the high-energy absorption, low weight, and cost-efficiency of advanced high-strength steels. Collaborating closely with your AHSS supplier allows your BIW components to achieve optimal designs for both automotive performance and crash safety.