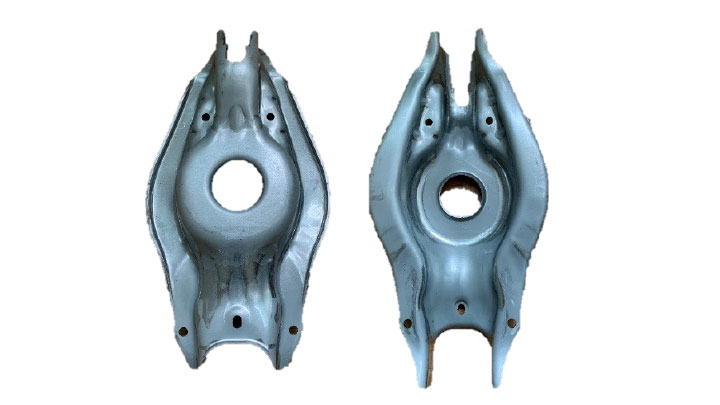

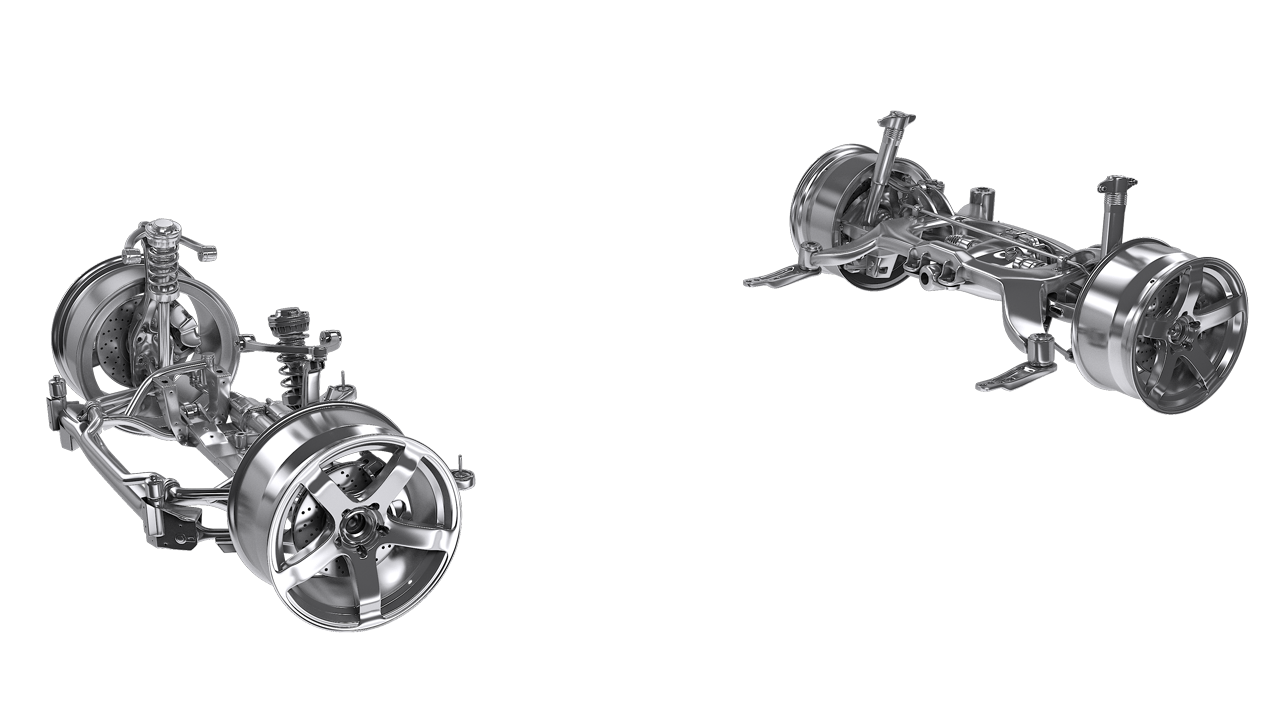

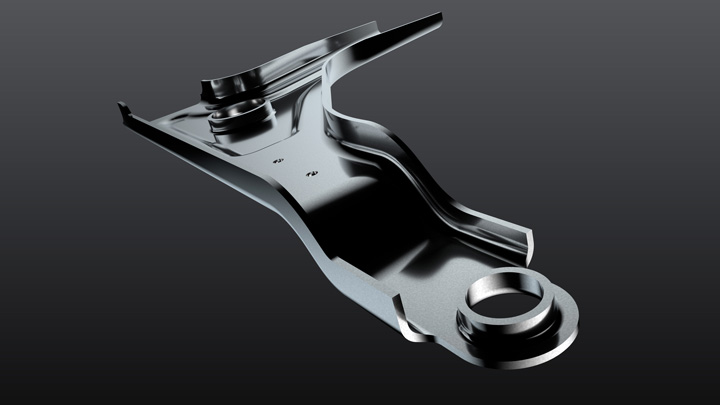

Car chassis components in AHSS steel

Chassis components need to meet several performance requirements, including crash worthiness, durability, peak loads, and noise/vibration/harshness (NVH) comfort needs. Advanced high strength steels — combining superior strength, formability, and fatigue resistance — enable chassis part designers to deliver high-performance parts with lower weight and in a cost-efficient way.