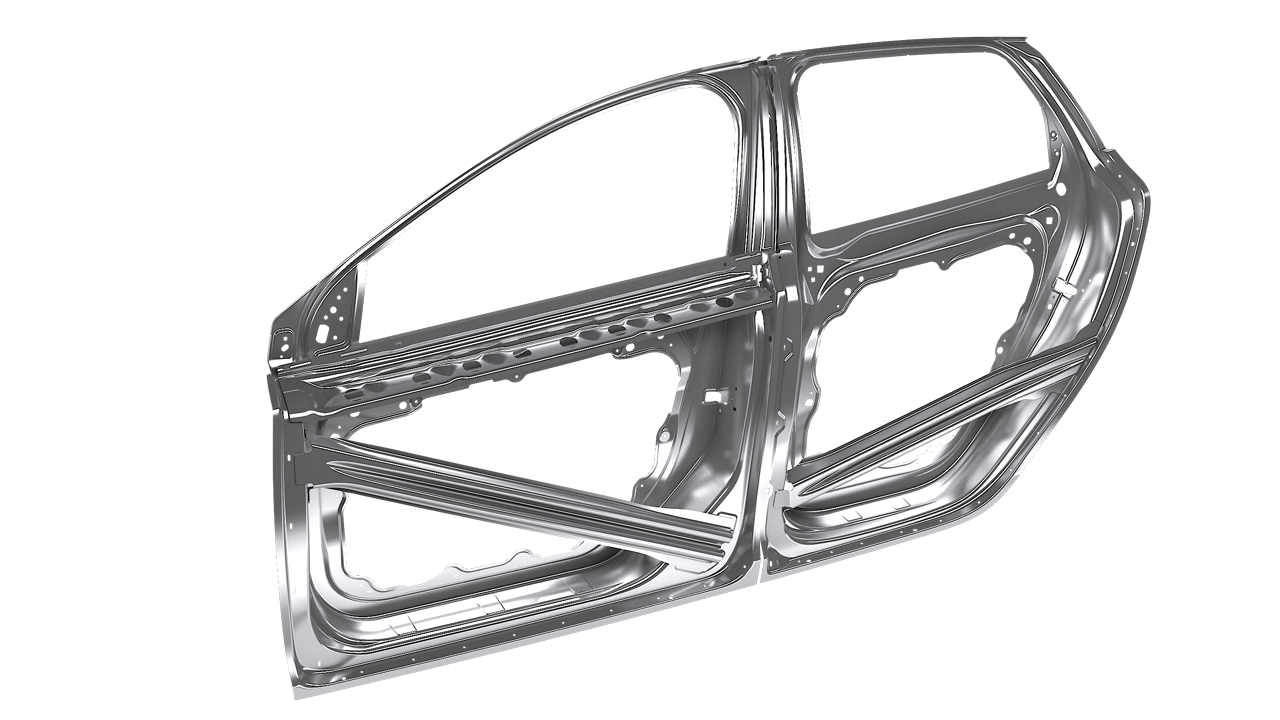

Side-impact beams and increased survival space

Side-impact automobile collisions, in general, result in more severe injuries than other types of collisions. Severe injuries to both upper and lower body can occur if the survival space is inadequate. Using optimized designs and advanced high strength steel grades for side-impact beams can significantly increase survival space in cars, helping to protect drivers and passengers during side impact crashes.

Side-impact beams achieve 5-star crash performance – at a lighter weight

For a new design for side-impact car door beams, a Tier 1 supplier needed to improve crash test performance, corrosion resistance, and cost efficiency – while lowering weight. Aluminum proved to be too costly, while press hardening steel would require investments in hot-forming presses, as well as slower production times.

Instead, the Tier 1 chose Docol® CR1500M-EG in 1.0 mm thickness. The martensitic 1500 MPa side-impact beams helped the car achieve a 5-star crash safety rating for side impacts while their 1.0 mm thickness kept the car door light in weight. Plus, the electrogalvanized metal coating provides the required level of corrosion resistance at a cost-efficient price point.