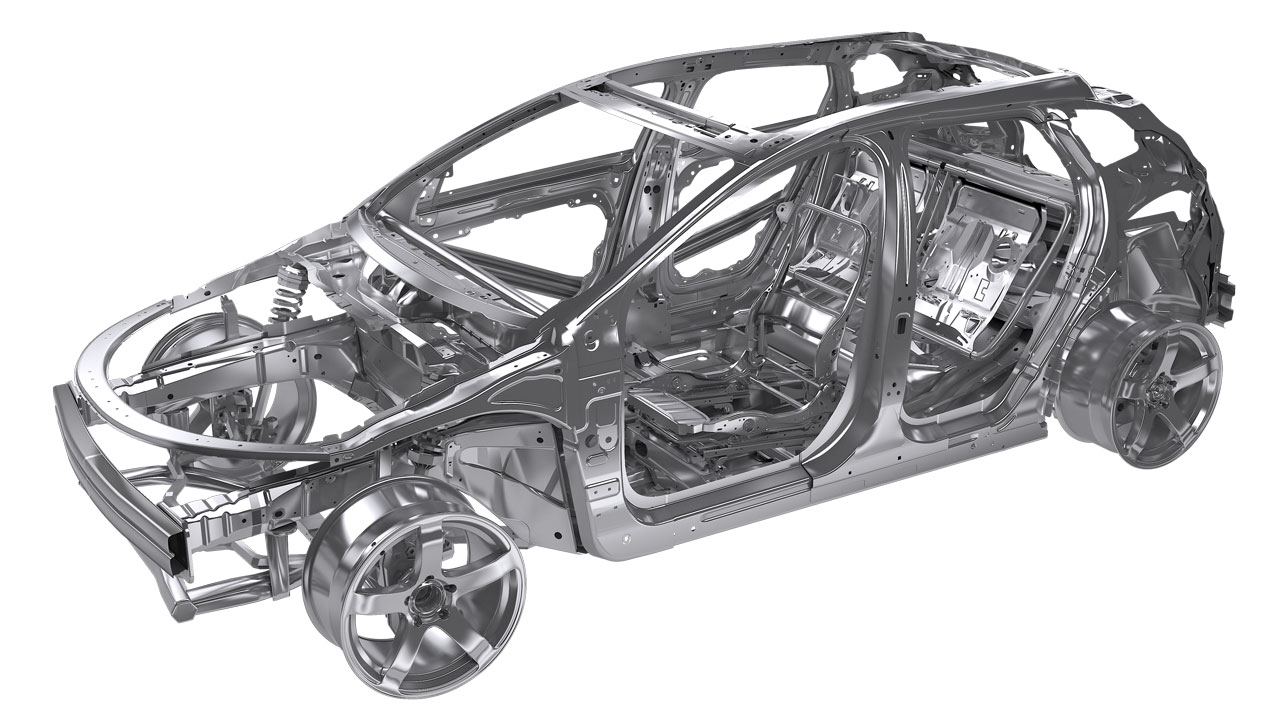

Automotive steel applications

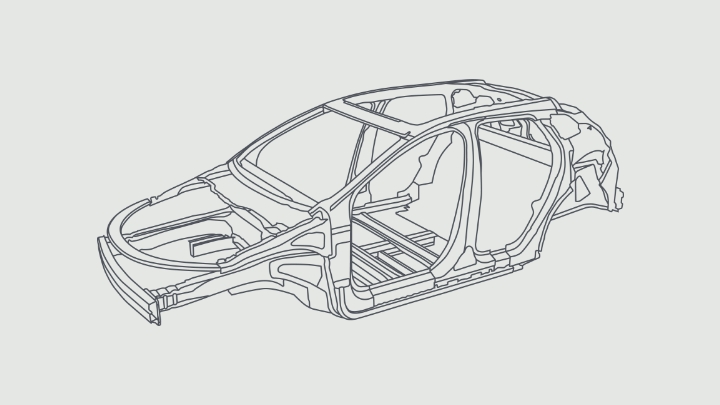

Docol® steel grades serve specific design purposes and are chosen by designers for a wide range of applications and used by OEMs and tier suppliers in millions of vehicles around the world.

Docol® steel grades serve specific design purposes and are chosen by designers for a wide range of applications and used by OEMs and tier suppliers in millions of vehicles around the world.

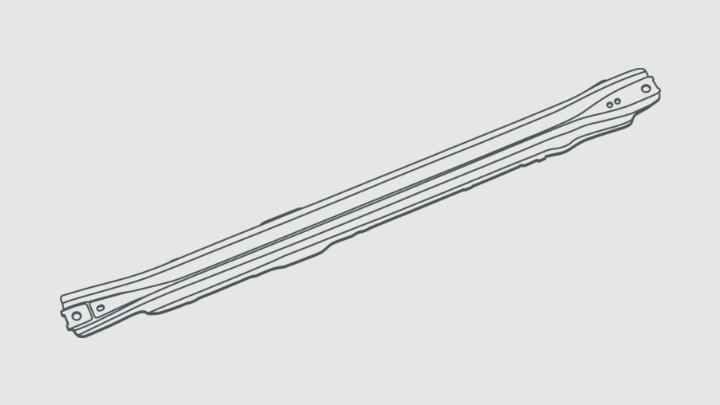

Parts such as sill reinforcements and cross-members must have both high-energy absorption capabilities and low weight. Stiffness can be maintained with optimized shape.

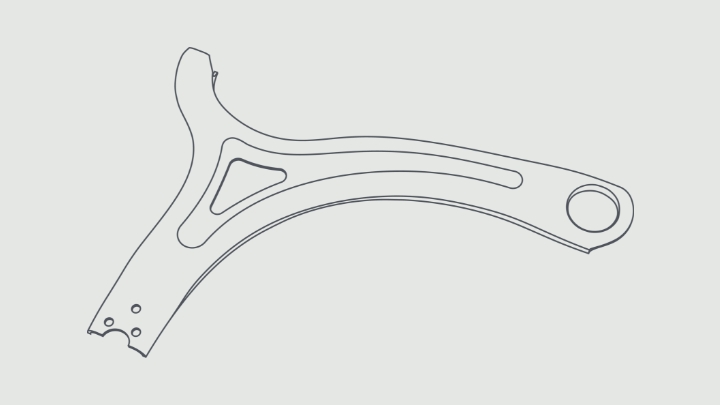

High-strength steels provide chassis with excellent formability and fatigue resistance properties.

AHSS steels provide high-force absorption for bumper reinforcements while achieving major weight reduction.

The high-strength levels of AHSS steel result in major weight reductions when upgrading side impact beams.

Car seats provide a critical safety structure for occupants. Advanced high steel steels can be used throughout the seat frame, significantly reducing their weight while meeting or exceeding current safety requirements.

Electric car batteries are expensive and hazardous if damaged in a crash. They also require underside protection from road debris and an enclosure that contains battery liquids in the event of a collision. Docol AHSS steels can help to ensure the strongest EV battery protection with the lowest possible weight.

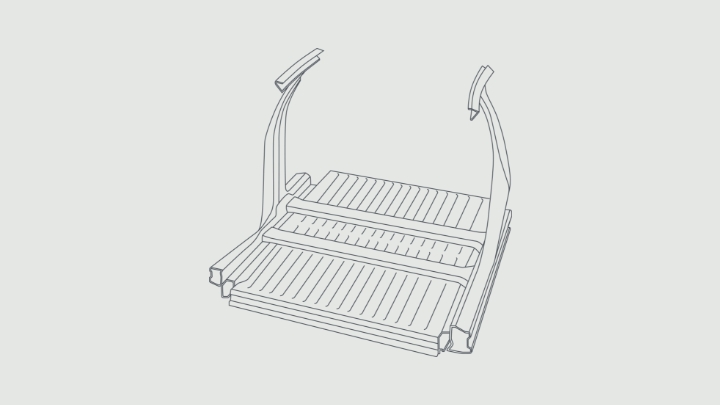

Cross members can further stiffen the car body, transfer side impact loads, and, in BEVs, protect battery packs. With their high strength, cross members made in AHSS and UHSS steels can increase both crash performance and vehicle responsiveness.

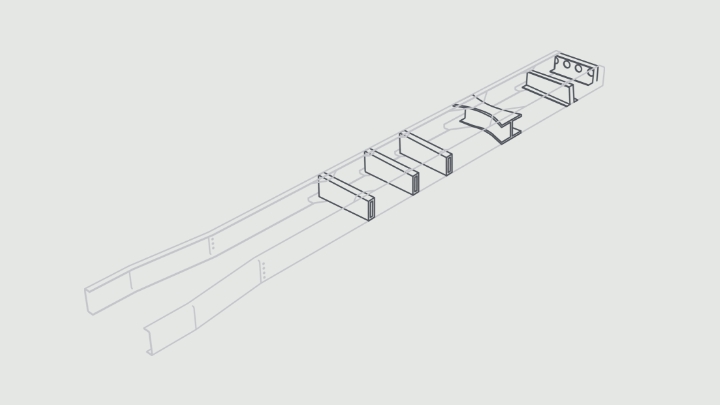

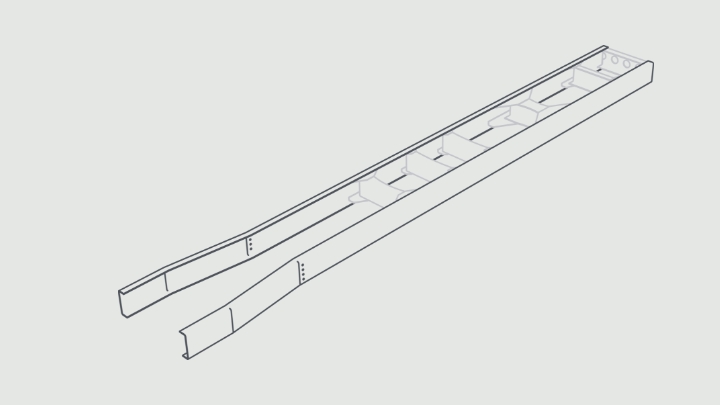

Frame rails, aka subframe rails, for trucks and light commercial vehicles (LCVs) require strength, stiffness, and fatigue resistance: AHSS and UHSS steels provide all that, plus significant lightweighting advantages.

Light commercial vehicles can optimize designs using AHSS and UHSS steels for lightweighting and strengthening their chassis, structural components and EV battery cages.

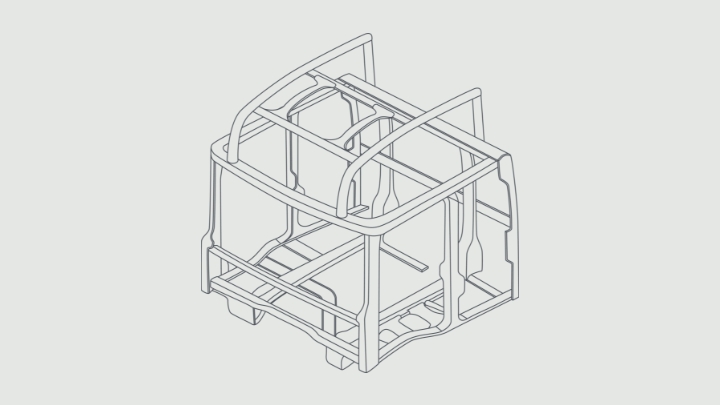

Truck cabin frames need to be light-in-weight, while providing for sustained driver comfort. With innovative designs and highly formable AHSS steels, designers can use complex geometries to increase cabin stiffness – reducing NVH – while also reducing driver blind spots.

New formulations and grades of Docol® high-strength steels enable you to produce vehicles that are stronger, lighter and more energy efficient.