1. What is stiffness?

Stiffness is the ability of a structure to resist deformation when subjected to external forces. It is a measure of the amount of force required to cause a certain amount of deformation in the structure. In practical terms, stiffness is the ability of a structure to withstand bending, twisting, compression, or stretching without losing its original shape. A stiffer structure deflects less under a specific load compared to a less stiff structure.

2. How is stiffness measured?

Stiffness can be measured through various practical methods. One common method is testing where a load is applied to the structure and the deformation is measured. Another method is vibration testing, where the natural frequency of the structure is determined and used to calculate stiffness. Specialized tools such as strain gauges and accelerometers can also be used to measure strain and vibration.

However, the stiffness of a single beam under a specific load can be quite accurately calculated using relevant formulas found in standards or literature. Alternatively, stiffness values can also be obtained from tables of section properties. Specially developed programs, or Finite Element Method (FEM), can be used to evaluate stiffness and deflection for more complex structures.

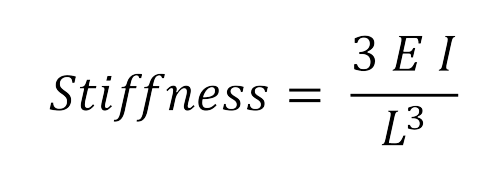

For example, the stiffness of a horizontal cantilever beam with a vertical point load at the free end can be calculated using the formula below.

where

I = moment of inertia (or second moment of area) of the beam's cross-section

L = length of the beam.

The values for E and I can be obtained from material data tables or calculated using appropriate equations. The SSAB Design handbook can be used to calculate I as well as other examples how to calculate the stiffness for other geometries.

3. What is deflection?

Deflection is the deformation or movement of a specific point in a structure from its original position due to forces applied to the structure. When a force is applied to a structure, it causes stress and strain, which in turn leads to deflection. Deflection can be linear, angular, or a combination of both, depending on the type and orientation of the force applied. Deflection can also be caused by environmental factors, such as changes in temperature and moisture content.

4. What are the main types of structural stiffness?

Structural stiffness is the ability of a structure to resist deformation or deflection when subjected to an external load. The most common types of structural stiffness are bending stiffness (flexural stiffness) and torsional stiffness. Bending stiffness is the ability of a structure to resist bending or flexure, while torsional stiffness is the ability to resist twisting. However, there are other types of stiffness that may also be important for specific structures, such as axial, lateral, shear stiffness and rotational stiffness.

The amount of deflection and load that causes a particular type of deflection depends on the type of stiffness involved.

- Axial stiffness, the elongation is related to the magnitude and direction of the axial load applied.

- Lateral stiffness, the deflection is related to the magnitude and direction of the lateral load applied.

- Shear stiffness, the deflection is related to the magnitude and direction of the shear force applied.

- Bending stiffness, the flexure is related to the magnitude and distribution of the load applied, as well as to the span and cross-sectional properties of the structure.

- Torsional stiffness, the twist is related to the magnitude and direction of the torque applied, as well as to the shape and size of the structure's cross-section.

- Rotational stiffness, the rotation is related to the magnitude and direction of the rotational moment applied.

These factors are all considered in engineering design to ensure that a structure is designed to resist the specific types of loads and deflections that it is likely to experience during its intended use.

5. How can bending stiffness be increased?

Bending stiffness is the ability of a structure to resist bending or flexure when subjected to a load. It is related to the moment of inertia (I) of the beam's cross-section under bending load. The moment of inertia is a measure of how far the cross-sectional area is positioned from the neutral axis. A larger moment of inertia indicates a more rigid structure. Thus, bending stiffness can be increased by increasing the moment of inertia of the beam's cross-section. SSAB’s design handbook is a tool for calculate the stiffness for different geometries.

To increase the moment of inertia of a beam's cross-section, the shape and dimensions of the cross-section can be altered. One common way to achieve this is by increasing the height of the beam, which moves more of the cross-sectional area away from the neutral axis. When the height of the beam is limited, increasing the width or thickness of the flanges is another common approach. Other techniques for increasing bending stiffness may involve using stiffeners, such as edge folds or grooves, or by using additional supports such as braces, beams, columns or trusses.

6. How can torsional stiffness be improved?

The torsional stiffness of a single beam depends solely on its torsional sectional properties for a given material. Closed sections, such as tubes or closed channels, generally offer better torsional rigidity and warping resistance than open sections due to a more uniform distribution of material around the cross-section. Regrettably, there are no exact analytical equations for finding torsional stiffness of non-circular sections due to wrapping deformation. However, in general, restraining the wrapping deformation of the end section or increasing the outer dimensions of the structure may improve torsional stiffness.

To improve the torsional stiffness of a structure, closed sections can be used instead of open sections, where possible. However, closed sections may not always be practical or cost-effective. In these cases, other measures may include increasing the thickness of the section or using stiffeners such as ribs or flanges. Additionally, the wrapping deformation of the end section can be restrained, and the outer dimensions of the structure can be increased to improve torsional stiffness in closed sections.

7. How can the global stiffness of a structure be improved?

The global stiffness of a structure depends on the stiffness of each member and how the members are joined and work together. Unfortunately, there is no general solution to improve global stiffness, as it depends on the specific characteristics of the structure. However, the first step is usually to identify the type of stiffness that is most important for the structure. Once this is known, the global stiffness can be improved through a redesign of the structural members and connections. Analytical computations combined with simulations, often with Finite Element Analysis (FEA), allow for the evaluation of the stiffness of each member and how they interact with each other, thereby optimizing the design and improving its overall stiffness.

8. How can twist be reduced?

Twisting is the movement that occurs when a structure is subject to torsional load and subsequently rotates around its longitudinal axis. The twist can be minimized by increasing the torsional stiffness of the structure. The torsional stiffness can be increased by changing the way structural members are connected to one another, by changing the members’ cross sectional shape and increasing plate thicknesses.

Measures to reduce twist in a structure include utilizing closed profiles, such as tubes or closed channels, which offer better torsional rigidity and warping resistance compared to open sections. Additionally, changing the cross-sectional shape of members to a shape with a greater torsional rigidity, such as rectangular or circular shapes, can help improve torsional stiffness and reduce twist. Increasing the thickness of plates and/or increasing the outer dimensions can also improve torsional stiffness and reduce twist in structures.

9. How can deflection be reduced?

The deformation of a steel member is affected by its modulus of elasticity and its stiffness, which is influenced by its geometry, including the thickness of the material. By modifying the geometry of the member, it is possible to increase its stiffness and reduce deflection for all kinds of loads.

Using thicker material in the sections, adding stiffeners, or increasing the number of members are generally measures to increase the stiffness and reduce deflection in steel structures.

For example, one way to reduce deflection in a steel member subjected to bending is to increase the moment of inertia (I) of the cross-section. This can be achieved by modifying the design of the cross-section, such as by positioning most of the cross-sectional area far from the neutral axis. This increases the stiffness of the member and reduces its deflection.

10. How does steel upgrading with the same geometry influence the stiffness?

When upgrading a steel design by increasing the yield strength without changing its overall geometry, the thickness of the upgraded structure is often reduced to save weight while maintaining the same strength as the original design. However, reducing the thickness also reduces the stiffness of the structure, which may require modifications to the design to restore the stiffness to an acceptable level and ensure that the deformations do not exceed allowable limits.

11. How does the material yield stress correlate to the bending stiffness?

12. Does high-strength steel have a higher stiffness than regular steel?

No, the stiffness of a steel member is primarily determined by its Young's modulus and geometry, not at all by its strength. Although high-strength steels have a higher yield strength than regular steels, their Young's modulus values are typically similar, resulting in similar material stiffness. The geometry of the cross-section is the primary factor that determines a member's stiffness.

13. Does a structure of high-strength steel have lower deflection than one of regular steel?

No. Deflection is independent of yield strength. The deflection of a structure under a specific load is determined by its stiffness, which depends on the material's Young's modulus, the geometry of the cross section, and the position or type of supports. While high-strength steels have a higher yield strength than regular steels, their Young's modulus values are typically similar, resulting in similar material stiffness. Yield strength only affects the maximum stress a material can withstand before plastic deformation occurs.

The typical Young's modulus value of steel is around 200-210 GPa. Other common materials and their Young's modulus values include aluminum alloys (70 GPa), titanium alloys (80-120 GPa), and concrete types (30 GPa ± 10 GPa). However, note that some of these values can vary depending on the specific material constitution.

14. What are the consequences of low stiffness in a structure?

Low stiffness in a structure means that it will deflect more under a given load. Stiffness is a measure of how much a structure resists deflection under the load applied while staying within its elastic range, that is when the structure returns to its original shape after unloading. Low stiffness can be caused using flexible materials, the presence of weak or unsupported structural elements, or an insufficient cross-sectional area. Therefore, a less stiff structure will deflect more and may experience greater deformation, leading to potential damage or failure if the deflection exceeds the allowable limit.

To ensure sufficient stiffness, it is important to consult applicable design codes and standards, which may vary across regions. In addition, it is crucial to adhere to industry standards and regulations when designing structures. For example, in North America, the American Society of Civil Engineers (ASCE) 7 standard provides guidance on wind, seismic, and other loads for building design, while the International Building Code (IBC) sets minimum requirements for structural design and safety. In Europe, the Eurocode system is commonly used, which includes design standards for different types of structures such as Eurocode 3 for steel structures and Eurocode 7 for geotechnical design. In the Asia-Pacific (APAC) region, countries may have their own national design codes and standards, such as the Chinese National Building Code for building design in China or the Japanese Industrial Standards for industrial design in Japan.

15. When can low stiffness be critical?

Low stiffness can become a critical issue for structures when it results in excessive deflection under load. As low stiffness leads to high deflections, the functionality of the structure may be compromised, potentially causing damage or even complete failure. Therefore, it is essential to ensure that deflection stays within the allowable limits. Adequate stiffness is crucial to meeting structural safety and functionality requirements.

To prevent low stiffness from becoming a critical issue, it is important to consider the intended use and load requirements of the structure during the design phase. This includes choosing appropriate materials and structural elements with sufficient strength and stiffness, and ensuring that the cross-sectional area of the structural members is adequate to resist the loads. Additionally, adhering to applicable design codes and standards is crucial to ensuring that the structure meets the required safety and performance criteria.

16. Is Strenx stiffer than other steels?

No, Strenx, like all other steels, has the same Young's modulus, which is a fundamental material property that determines stiffness. Therefore, Strenx does not exhibit greater stiffness compared to other steels.

To choose a steel with desired stiffness, it is important to consider its Young's modulus value, which is typically around 200-210 GPa for steel. However, when choosing a steel, the designer should consider many other factors, such as material strength, fatigue strength, toughness, corrosion resistance and availability. It also is essential to consult industry standards and design codes to select the appropriate steel for a given application.

17. Can deflection be reduced when upgrading to Strenx®?

Upgrading to Strenx®, a type of high-strength steel, typically involves reducing thickness to achieve weight savings. However, this reduction in thickness alone may result in an increase in deflection. While design changes can be made to address this issue, achieving a reduction in deflection when upgrading can be challenging. It is crucial to carefully consider the structural requirements and design changes to achieve optimal performance while minimizing deflection.

18. How much does deflection increase after an upgrade?

When upgrading a structure, thickness may be reduced to achieve weight savings but can result in increased deflection. Designers need to carefully consider the impact of any thickness reductions on structural safety and functionality requirements, including allowable deformation. The allowable increase in deflection can vary depending on the load, design geometry, and structural requirements of the application. For example, the degree of reduction in the moment of inertia due to the thickness reduction can affect the amount of deflection increase for a bending loaded member.

19. Will lower structural weight affect stiffness?

Yes, reducing the weight of a steel structure often involves reducing its thickness, which results in decreased stiffness. This reduction in stiffness can impact the structural performance and safety of the application; this makes it important to consider the implications carefully. However, with appropriate design changes, it is possible to mitigate the effects of decreased stiffness and ensure that the structure meets the necessary requirements.

20. Does a structure made of high strength steel deflect more than one made of mild steel?

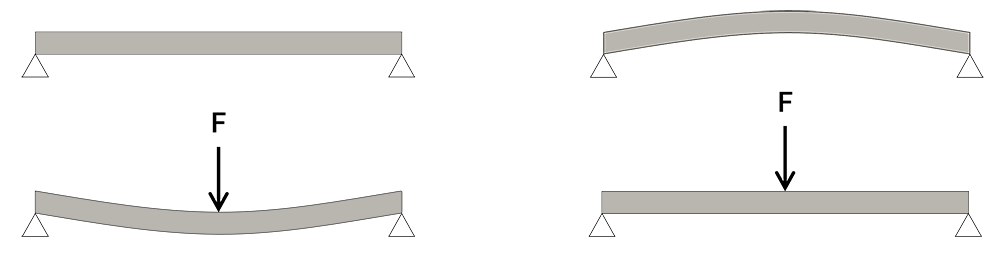

The answer is not straightforward and depends on the specific application. Upgrading a mild steel structure to high-strength steel often involves a reduction in thickness to achieve weight savings. This reduction in thickness results in a reduction in stiffness, which increases the deflection of the high-strength steel structure. If extra deflection is not acceptable, it can be addressed through design changes, such as modifying dimensions or adding reinforcements to maintain the necessary stiffness for the application. Another way to handle the deflection is to pre-bend, meaning to design with a “deflection” in the opposite direction of the deflection when the structure is loaded (see illustration below).

However, in some cases, the extra deflection may be acceptable given the benefits of having a lighter structure. For example, in applications that require dent resistance, the increased flexibility of a high-strength steel structure made with high-strength steel like Hardox® wear plate can even be beneficial.

The information in this report is only applicable to SSAB’s products and should not be applied to any other products than original SSAB products.

This report provides general results and recommendations for SSAB steel products. This report is subject to SSAB’s Terms of Use. It shall be the user's responsibility to verify that the information contained herein is correct and is suitable to be used for the particular purpose and application of the user. The report is intended to be used by professional users only who possess adequate expertise, qualification and knowledge for the safe and correct use of the results and recommendations in this report. This report is provided “as is”. The use of the report is at user’s own discretion and risk and that users will be solely responsible for any use of this report. SSAB disclaims any liability for the content or potential errors of this report, including but not limited to warranties and condition of merchantability or fitness for a particular purpose or suitability for individual applications. SSAB shall not be liable for any kind of direct or indirect damages and/or costs related to or arising therefrom, whether special, incidental, consequential or directly or indirectly related to the use of, or the inability to use, the report or the content, information or results included therein.